5 Tips to Safely Handle Hazardous Materials During Manual Demolition

When it comes to manual demolition projects, cutting corners can lead to costly mistakes and serious consequences. Attempting to tackle these tasks without professional help not only increases the risk of accidents, but can also result in structural damage, personal injury, or even legal issues.

Professional demolition services bring the expertise and equipment necessary to safely handle complex removal tasks, ensuring that no matter how intricate the project is, it is completed with precision and care. By hiring experts, you are ensuring that all safety protocols are followed and that hazardous materials, like asbestos or lead, are properly disposed of, preventing harm to both workers and the environment.

In addition to safeguarding your property and well-being, professional demolition services help minimize the environmental impact of a project. Trained contractors are equipped to identify recyclable materials and handle waste disposal in accordance with local regulations, significantly reducing the project’s carbon footprint.

By using proper techniques and tools, they also prevent damage to the surrounding areas that could otherwise disrupt nearby structures or utilities. Ultimately, enlisting the right experts is about more than just efficiency; it is about preserving safety, compliance, and the environment throughout the entire demolition process.

Key Safety Tips for Handling Hazardous Materials During Manual Demolition Projects

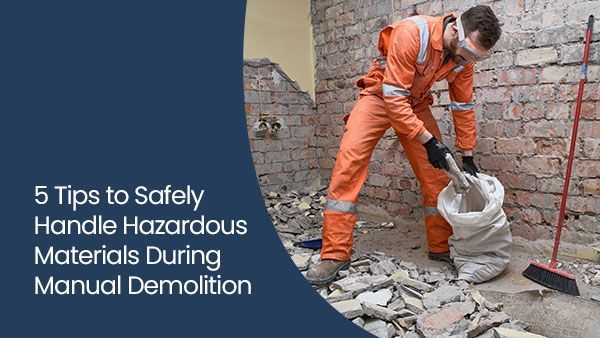

Handling hazardous materials during manual demolition projects requires careful attention to detail and a strong focus on safety. Properly managing these materials is crucial to prevent accidents, health risks, and environmental damage.

Let’s dive into some essential safety measures to keep in mind to ensure a secure and compliant demolition process.

1. Proper identification of hazardous materials

The first and most important step in any manual demolition project is the identification of hazardous materials, such as asbestos, lead paint, or mould. These materials pose many health risks if not handled properly, and a failure to identify them can lead to severe consequences.

A reputable demolition contractor is equipped to conduct a thorough inspection to assess the presence of hazardous materials, ensuring the safety of workers and the environment.

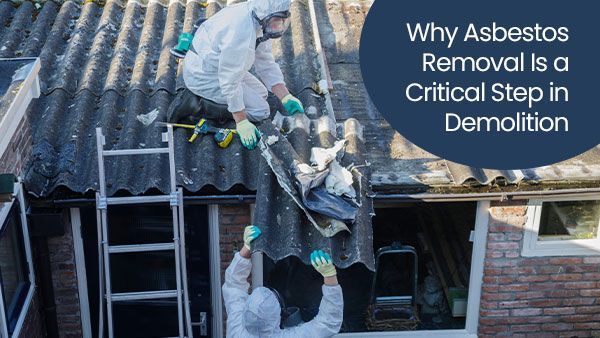

For instance, asbestos removal requires specialized techniques and equipment to avoid contamination, and it is critical to test materials beforehand to determine whether they are hazardous.

Correctly identifying hazardous materials upfront ensures that the demolition and excavation process follows necessary safety protocols, preventing harm and enabling effective hazardous waste disposal.

2. Use of personal protective equipment

When dealing with hazardous materials during manual demolition, the use of personal protective equipment (PPE) is essential to maintaining construction safety. PPE, such as respirators, gloves, protective clothing, and safety goggles, serves as a barrier between workers and harmful substances, ensuring their protection throughout the project.

Asbestos removal, for example, requires workers to wear high-quality respirators to filter out toxic particles in the air, while gloves and full-body suits prevent direct contact with materials like lead paint or mould.

A professional demolition company will ensure that the appropriate PPE is provided and enforced, safeguarding workers against exposure to hazardous materials that can have long-term health effects if mishandled.

3. Safe disposal and containment

When working with hazardous materials in manual demolition, proper disposal and containment are essential for both safety and environmental protection.

Hazardous waste disposal is a highly regulated process, especially for materials like asbestos, which require specialized containment and transportation methods. Once hazardous materials are safely removed from the structure, they must be placed in sealed containers that are clearly labelled, thus preventing accidental exposure.

These materials must then be transported to certified disposal facilities that comply with local regulations to ensure that the substances are disposed of responsibly. A professional demolition contractor will adhere to strict guidelines for the disposal of hazardous waste, preventing contamination of the environment and protecting public health throughout the project.

4. Ventilation and air quality control

Proper ventilation and air quality control are critical during manual demolition projects that involve hazardous materials.

Asbestos removal and the demolition of structures containing toxic substances release harmful dust and particles into the air, which can be inhaled by workers and bystanders, leading to serious health issues. To mitigate these risks, it is essential to use ventilation systems that maintain a controlled airflow, keeping hazardous materials confined to the work area.

Negative pressure systems are often employed during demolition and excavation to ensure that contaminated air does not escape. By maintaining air quality and ensuring proper ventilation, a demolition company can safeguard the health of everyone on the job site, making it an essential part of construction safety protocols.

5. Specialized training and licensing

Handling hazardous materials in a demolition project requires specialized knowledge, making proper training and certification essential for construction safety.

Workers involved in asbestos removal or the handling of other toxic substances need to be thoroughly trained in the specific methods for safely dealing with hazardous materials. A licensed demolition contractor is required to adhere to stringent safety regulations and protocols for the handling, containment, and disposal of hazardous waste.

From knowing how to use protective equipment to understanding how to conduct safe manual demolition and excavation, a trained demolition team is essential to reducing the risks associated with hazardous materials.

Without specialized training and certification, the project becomes much riskier, making it vital to trust professionals who are licensed to manage hazardous materials safely and effectively.

How MOD Demolition Can Guarantee Safe Manual Demolition and Proper Hazardous Waste Disposal

If you need a building demolished, and you want to ensure that this project is done safely and responsibly, especially when handling hazardous waste disposal, you can count on MOD Demolition. We maintain the highest possible standards of safety all throughout the demolition process.

Our team of experienced professionals specializes in providing efficient, safe, and meticulous manual demolition services for both residential and commercial clients. Our manual demolition approach allows for careful deconstruction, preserving elements of the structure you wish to keep intact while preparing the space for renovation or rebuilding.

With each project tailored to the specific needs of our clients, we focus on minimizing disruptions and ensuring that your investment remains protected throughout the process.

One of the critical aspects of our manual demolition services is our commitment to handling hazardous materials, such as asbestos, with the utmost care and responsibility. Indeed, our team is fully trained and equipped to safely remove and dispose of these hazardous materials.

We take every necessary precaution to ensure that hazardous waste disposal, including the safe removal of asbestos, is handled in strict compliance with safety regulations. By trusting our licensed and trained professionals, you can rest assured that your home or business is in safe hands, with proper hazardous waste disposal methods in place to protect both your health and the environment.

For more information about our hazardous waste disposal methods, or to learn more about why we are a top-notch demolition company, call MOD Demolition at 249-449-0018 or contact us here.